High-precision Robot Design & Control

Industrial Transfer Robot

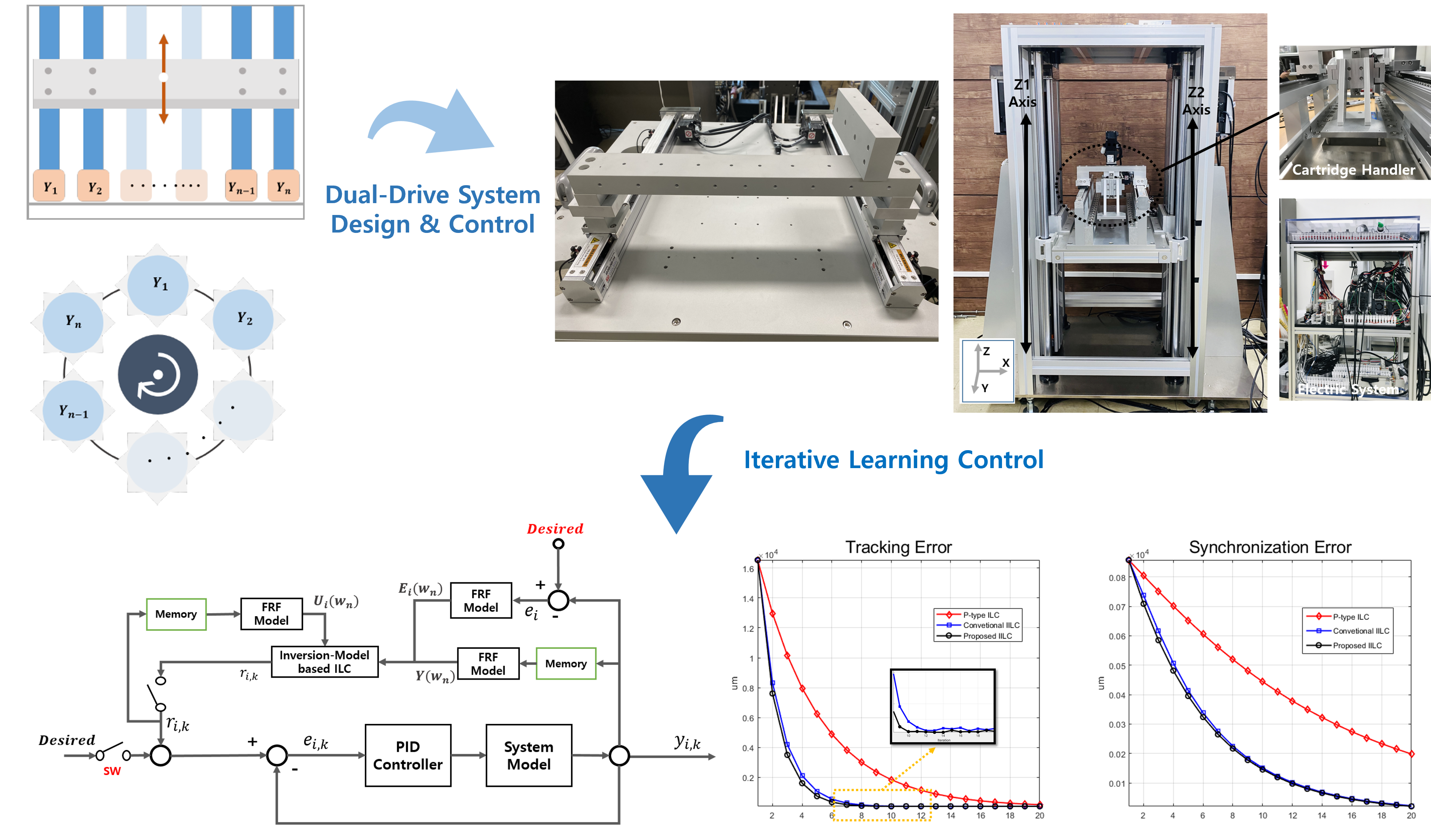

We are conducting research on the design and control of transport robots required in industries that demand high precision. To transport heavy objects, we are designing a Dual-drive system and developing a tracking & synchronizing control algorithm to manage both driving axles. By applying a model-based repetitive control algorithm, tracking and synchronizaion error is to be minimized.

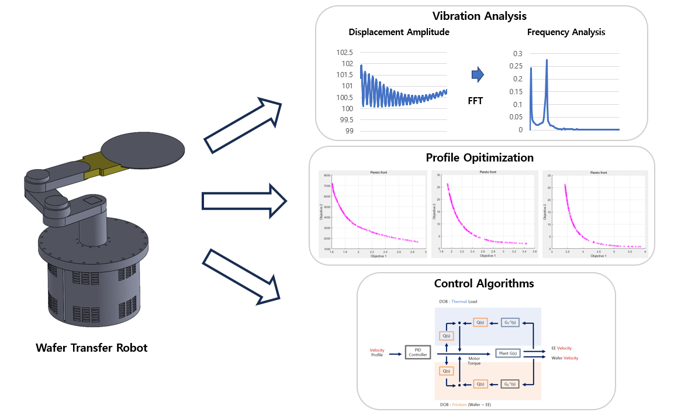

Wafer transfer robots are used to transfer wafers in the semiconductor manufacturing process. In the semiconductor manufacturing process, the accuracy and stability of wafer transfer are very important. Therefore, in order to improve the accuracy and stability of wafer transfer, we analyze vibration in the dynamic situation of the wafer transfer robot, optimize the motion profile to minimize vibration, and study control algorithms to improve accuracy.

Soft Robot Mechanism Design & Control

Pneumatic Soft Rotary Actuator

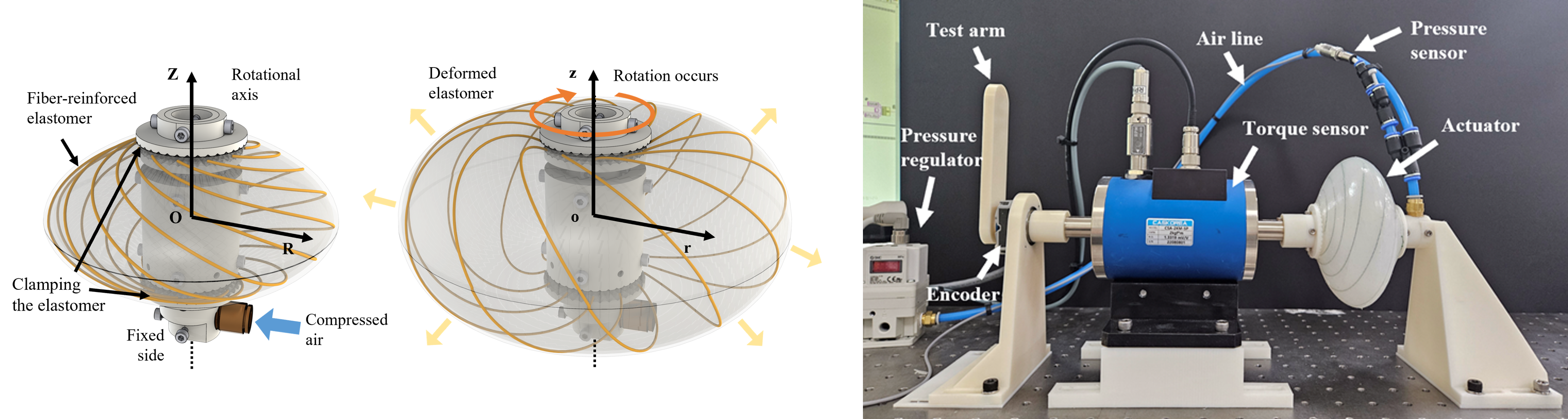

Soft actuators, mimicking the characteristics and motions of human muscles, present multiple benefits and have garnered significant attention in research area. Investigations encompass the design, methmatical analysis, and control of pneumatic soft rotary actuators. A standout trait of these actuators is their ability to deliver substantial rotation and considerable torque relative to their aspect ratio.

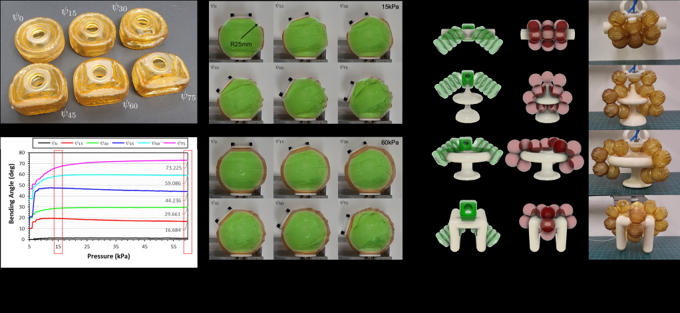

Multi-curvature and Variable Stiffness Soft Gripper

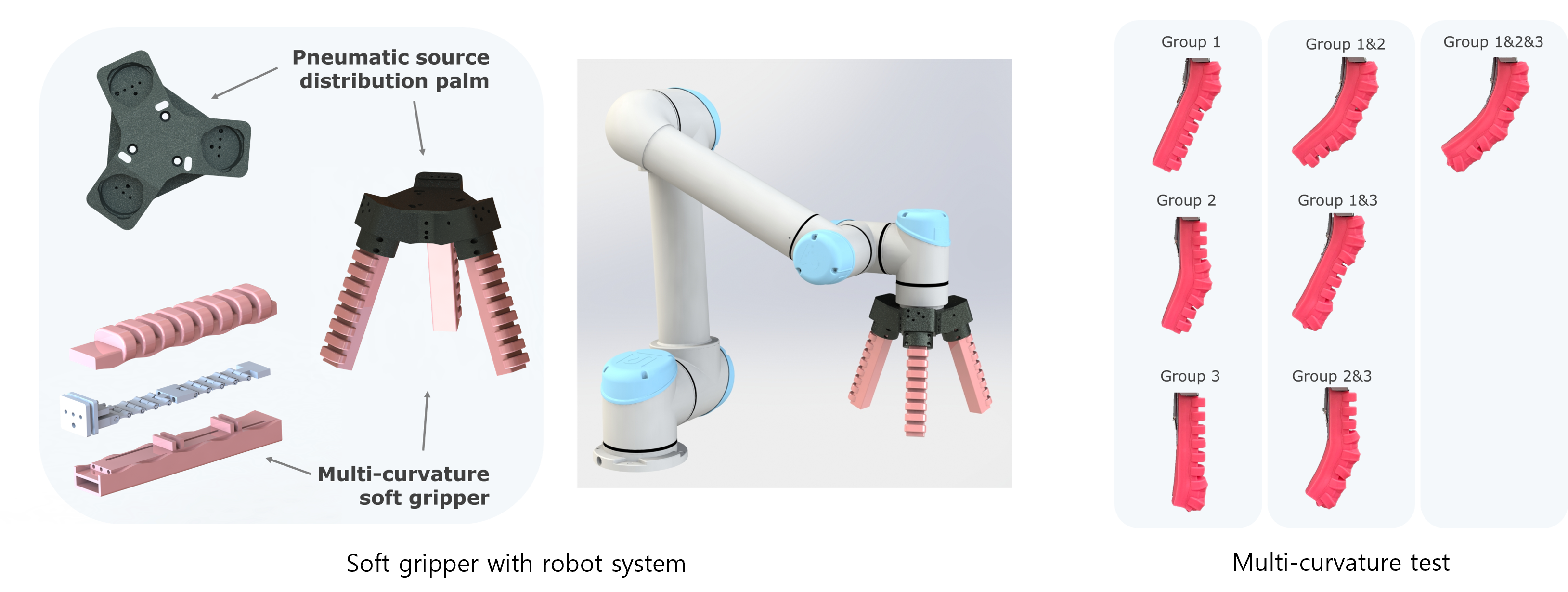

This research aims to develop a soft gripper robotic system capable of multi-curvature and variable stiffness. Conventional grippers struggle to handle objects with low surface stiffness, such as baked goods and agricultural produce. To overcome this limitation, we have developed a new soft gripper. To address the low stiffness inherent in soft grippers, we implemented a variable stiffness mechanism, enabling the gripper to handle objects weighing up to 1.8 kg. Additionally, incorporating a multi-curvature mechanism allows for realizing seven distinct curvatures. This innovation is expected to find broad applications in sectors where conventional grippers have been inadequate, including bakeries, agriculture, and the service industry.

/>

Configurable Soft Robot

We research a design method that can drive the deformation of a soft robot to a precise target without any control. In previous research, designing soft actuators to attain a predetermined actuation stroke has been challenging due to the complexities of deformation analysis. This issue often made it hard to achieve user-specified kinematics in soft robotics. However, ensuring the actuator converges to the target upon inflation can be achieved by the surface geometry-based method that determines the initial shape of the actuator based on its desired deformed shape. A notable advantage of our methodology is its ability to rapidly compute soft robot design without advanced complex continuum mechanics theories, making it adaptable to various scenarios.

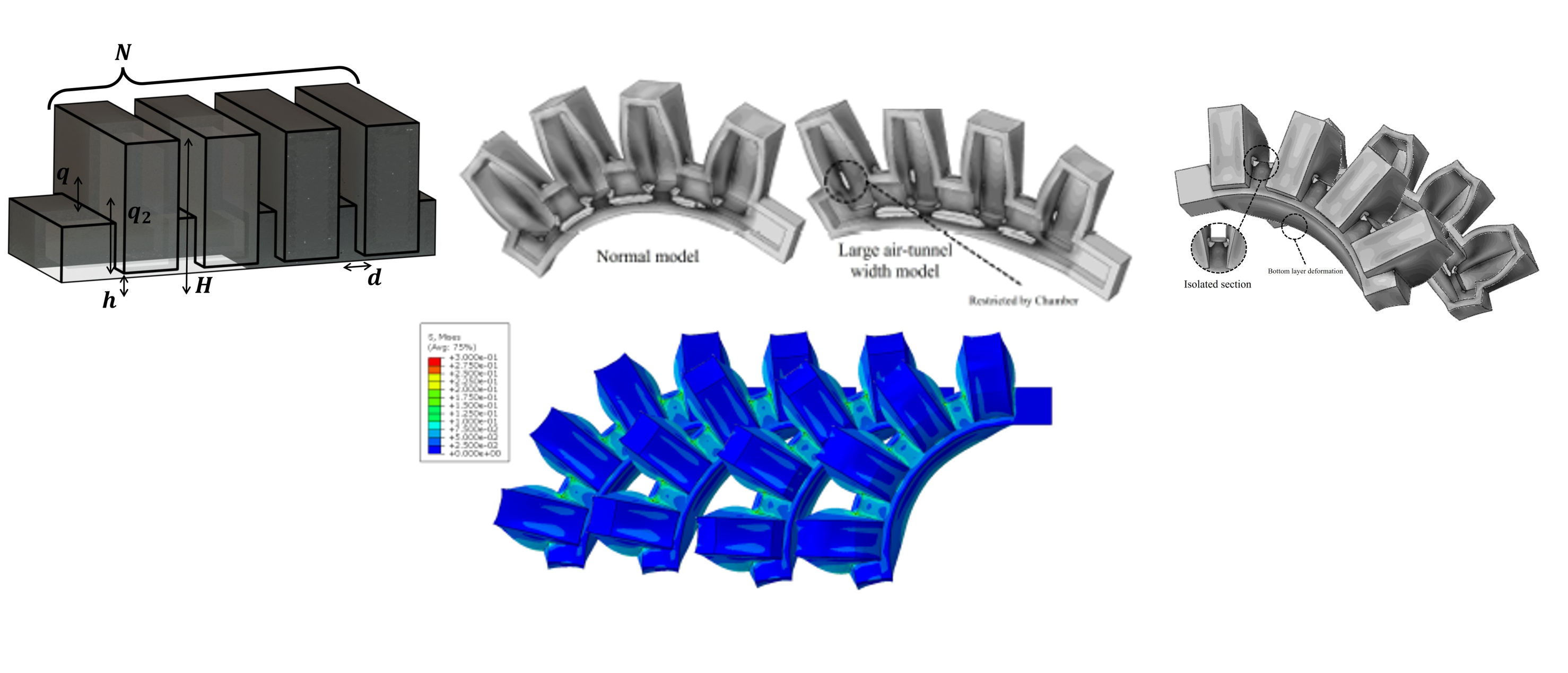

Soft Gripper Design Optimization

We designed the actuator by separating the chamber and the pneumatic passage away from the existing SPA(Soft Pnuematic Actuator). We made the chamber partially embedded in the air-tunnel, which is a pneumatic passage so that the curvature can be formed in the deformed state. We constructed an analytical model that can predict the actuating range by simplifying the divided parts, and based on this, we checked the curvature using FEM simulation. We optimized the SPA design to maximize the actuating range under the same limiting conditions, and the optimization proceeded in the order of chamber, air-tunnel, and other parameters. In addition to the optimization progress, we improved the accuracy of the analytical model using the simulation results, and we can easily predict the curvature of the actuator through this model.

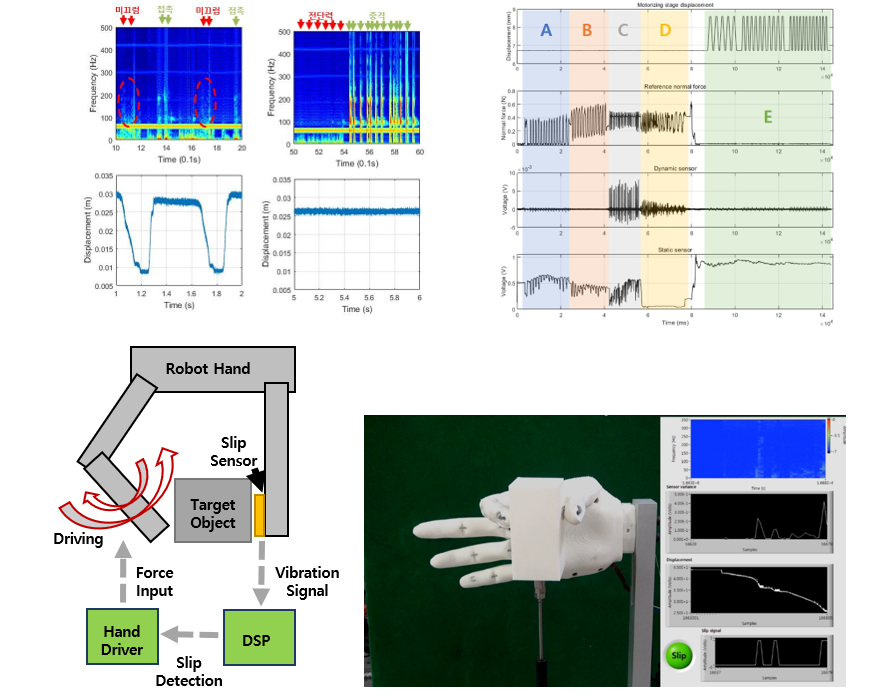

Soft Tactile Sensor

The Soft tactile sensor is a sensor that replaces a conventional rigid sensor. In our research, physical tactile values are detected by fabricated polymer sensors which have flexible and soft characteristics. The sensor can measure strain, pressure, detect, slippage and roughness in forms of electrical signals such as resistance or capacitance or voltage. Information of object surface is obtained through signal processing.

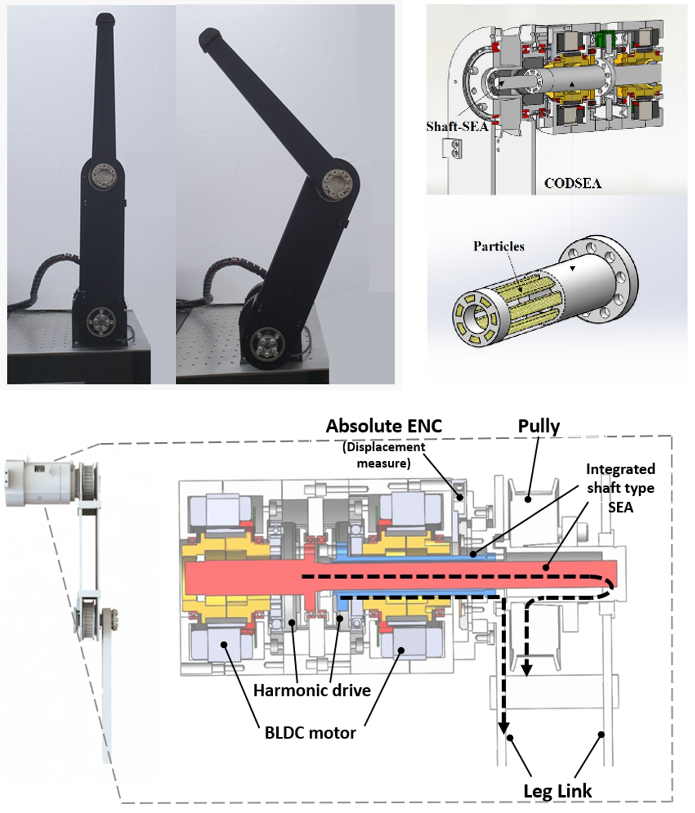

Variable Stiffness Mechanism using particle jamming phenomenon

This research aims to optimize variable stiffness mechanisms through theoretical modeling. Despite the widespread use of particle jamming in variable stiffness mechanisms, few theoretical models exist, primarily due to the system's complexity. Existing models also present limitations when applied to the field of robotics. In this study, we derive an energy-based theoretical model for particle jamming and detect force chains, which are critical for stiffness augmentation. In conclusion, the optimized particle jamming mechanism will be employed across various fields.

Compliant Mechanism Design & Control

Physical Coaxial Damping SEA

..ing

Hydraulic/Pneumatic Robot Manipulator Mechanism Design

Hydraulic Robot Manipulator

A hydraulic robot has been designed for impedance control experiments. It is comprised of hydraulic actuators, servo valves, encoders, and a 6-axis F/T sensor. The input for the hydraulic system is provided by the HPU (Hydraulic Power Unit). The designed robot is utilized for experiments involving heavy loads, which would be unattainable with electric motor robots. Currently, it has 5 axes, but there are plans to expand it to 6 axes in the future.

Pneumatic 3-dof Actuator

..ing